AI is transforming warehouse operations, cutting costs, and boosting efficiency. Here's what you need to know:

AI-powered systems are reshaping warehouses by integrating robotics, computer vision, and predictive analytics. This ensures faster, more accurate, and cost-effective order fulfillment. Whether you're scaling operations or reducing errors, AI offers measurable improvements across the board.

Building on the discussion of operational improvements, let's dive into the core AI technologies transforming order picking. These include robotics and autonomous systems, computer vision with machine learning, and predictive analytics powered by real-time data. Each addresses specific challenges while working together to streamline processes and boost efficiency.

Robotics and autonomous systems are reshaping warehouse operations by automating repetitive tasks and reducing the physical strain on workers. One standout example is Autonomous Mobile Robots (AMRs), which navigate warehouses using built-in sensors. These robots optimize routes without requiring expensive infrastructure changes.

Take GEODIS, for instance. Partnering with Locus Robotics at its Mount Juliet, TN facility, the company improved efficiency for Black Rifle Coffee Company. This collaboration led to a 70% increase in units picked per hour, jumping from 100 to 170, and slashed training time for new employees by 95%, reducing it from 8 hours to just 20 minutes.

"During peak, Locus support was on-site to make any necessary adjustments to the LocusBots in real time... We had a congestion issue with 10 bots in an aisle, and the support team was able to see what was going on and put in a flag for the LocusBots to go to a different aisle and wait, which eased the congestion immediately."

- Theresa Marsic, Director of Operations

Pick Assist Robots add another layer of efficiency. Rapyuta Robotics' platform has doubled productivity while maintaining a picking accuracy rate above 99.9%. These robots guide workers with optimized routes and integrate seamlessly with existing warehouse management systems (WMS) and enterprise resource planning (ERP) tools.

The Totes-to-Person method takes things further. By separating human tasks from robotic functions, inVia Robotics' system delivers a fivefold increase in picking productivity. Robots handle inventory transport, leaving workers free to focus solely on picking.

Other success stories include JD.COM, whose warehouse saw a 136% increase in units per hour after adopting ForwardX Robotics' case-picking solution for water distribution. Similarly, Avenue Shops experienced a 65% jump in daily shipped orders after implementing Hai Robotics' solutions.

While robotics tackles the physical aspects of order picking, computer vision ensures precision in item handling.

Computer vision technology enables AI systems to identify, classify, and manage objects with incredible accuracy. This technology powers robotic arms for precise item handling and ensures optimal placement during picking operations.

Over the past decade, computer vision accuracy has skyrocketed. A 2022 MIT study revealed that object classification accuracy improved from 50% to 99%. Reflecting this growth, the global computer vision market grew from $9.4 billion in 2020 to a projected $41.11 billion by 2030.

One practical application comes from WeWork, which implemented PackageX Receive. Using Optical Character Recognition (OCR) and computer vision, the system achieves over 95% accuracy in reading shipping labels across 57 languages. This reduced package processing time by 85%, saving employees an average of one hour daily per location.

Computer vision also enables automated barcode and QR code scanning, dimension validation, and label verification. Advanced systems use deep learning to estimate hand movements, ensuring correct items are packed and providing instant visual feedback for errors.

For example, KH Lloreda introduced a robot-based depalletizing system using MVTec HALCON software in 2021. This solution boosted productivity by 50%.

"We chose HALCON because it allows us to develop robust and reliable algorithms in a very short time."

- Irene Vázquez Martín, Junior Application Engineer at Cretec Cybernetics

While robotics and computer vision handle physical and perceptual tasks, predictive analytics ensures smarter decision-making with real-time insights.

Predictive analytics combines historical and real-time data to forecast demand, optimize stock placement, and enable proactive strategies. This technology also provides instant visibility into warehouse activities.

Integrating AI with labor management has proven highly effective, cutting logistics costs by 15%, improving inventory accuracy by 35%, and boosting service levels by 65%. This is especially valuable given that executives spend 37% of their time making decisions, with over half of that time often wasted.

Major players like Amazon and Walmart rely on predictive analytics to refine their operations. Amazon uses real-time inventory tracking and demand forecasting to optimize workflows, while Walmart analyzes purchasing patterns, seasonal trends, and even weather forecasts to predict demand with precision.

Predictive analytics extends beyond inventory management. Toyota, for example, uses real-time supplier monitoring to detect bottlenecks and fine-tune supply chain relationships, ensuring smooth production and just-in-time inventory.

"There is a need to be able to collect real-time data at key moments and share insights with ecosystem partners and employees in frontline roles in ways that make sense for them."

- Frank De Jong, Senior Digital Business Consultant at Orange Business Services

Another key application is labor optimization. AI algorithms analyze data to cross-train employees for various roles, showing which team members adapt best to different tasks. Companies can start small - focusing on areas like labor scheduling or demand forecasting - and scale up once they see results. These incremental improvements highlight the transformative role AI plays in streamlining order picking.

Case studies provide a glimpse into how AI is transforming order picking across industries. By showcasing the integration of robotics, computer vision, and predictive analytics, these examples highlight tangible benefits and advancements.

DHL has embraced AI-driven solutions to revolutionize its operations. In Miami, the company piloted DHLBots, which have since been deployed globally, achieving the ability to sort over 1,000 small parcels per hour with 99% accuracy. Partnering with Locus Robotics, DHL introduced 2,000 autonomous picking robots, leading to a 50% boost in efficiency, a 25% reduction in errors, and a 20% cut in labor costs. Meanwhile, its Resilience360 platform, powered by machine learning, reduced employee travel distances by 50% and increased productivity by up to 30%. DHL also experimented with Boston Dynamics' 'Stretch' robot, capable of transferring 700 pieces per hour, and implemented robotic arms in its eCommerce operations, achieving a sorting speed of just 3.6 seconds per item with nearly zero errors.

These innovations illustrate how combining robotics with real-time data analytics is reshaping logistics. During the peak season of November and December 2020, DHL Express recorded a 17.3% year-over-year increase in volume.

"The more we can use robots to complete repetitive or distant tasks in highly predictable, structured environments, the more we free up our employees to leverage their unique human capabilities." - Tim Tetzlaff, Global Head of Accelerated Digitalization, DHL Supply Chain

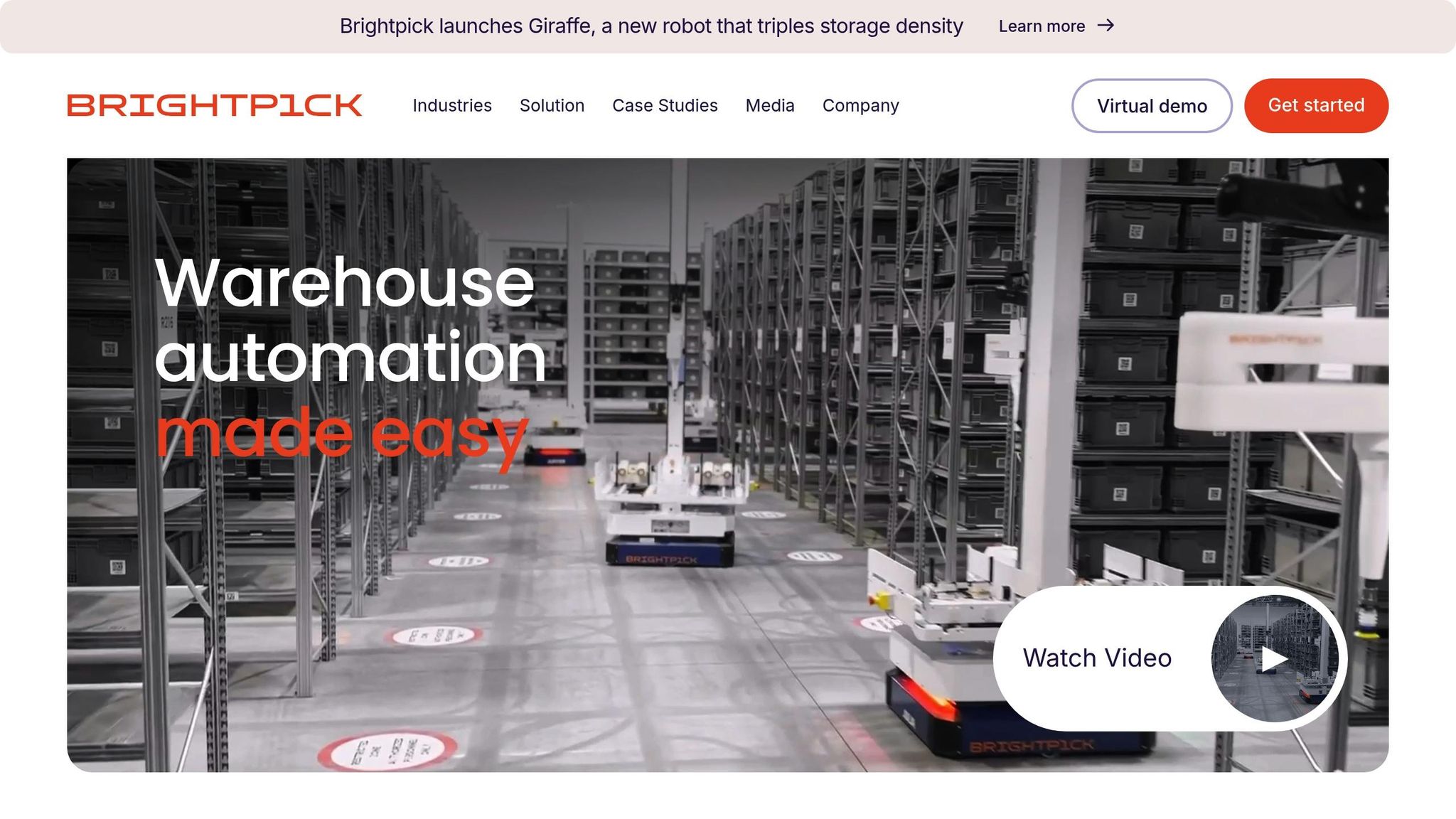

Brightpick's AI-powered system addresses challenges like managing extensive SKU inventories and fluctuating demand through the use of 3D machine vision, which continuously enhances performance.

For example, The Feed, a sports nutrition retailer managing 6,000 SKUs, transitioned from manual operations to automation by deploying 48 Brightpick Autopicker robots. This shift reduced their workforce from 50–100 employees to just 3–4, while increasing daily capacity to 50,000 items. The system delivered a return on investment within two months, slashing operational costs by 65%. These robots also integrate seamlessly with automated stations for handling heavy and fast-moving items, allowing the company to become cash flow positive within 60 days.

"We were able to go from 50-100 people to completely automated with the Brightpick solution. The payback period from Brightpick was immediate; we were cash flow positive within 60 days." - Matt Johnson, CEO of The Feed

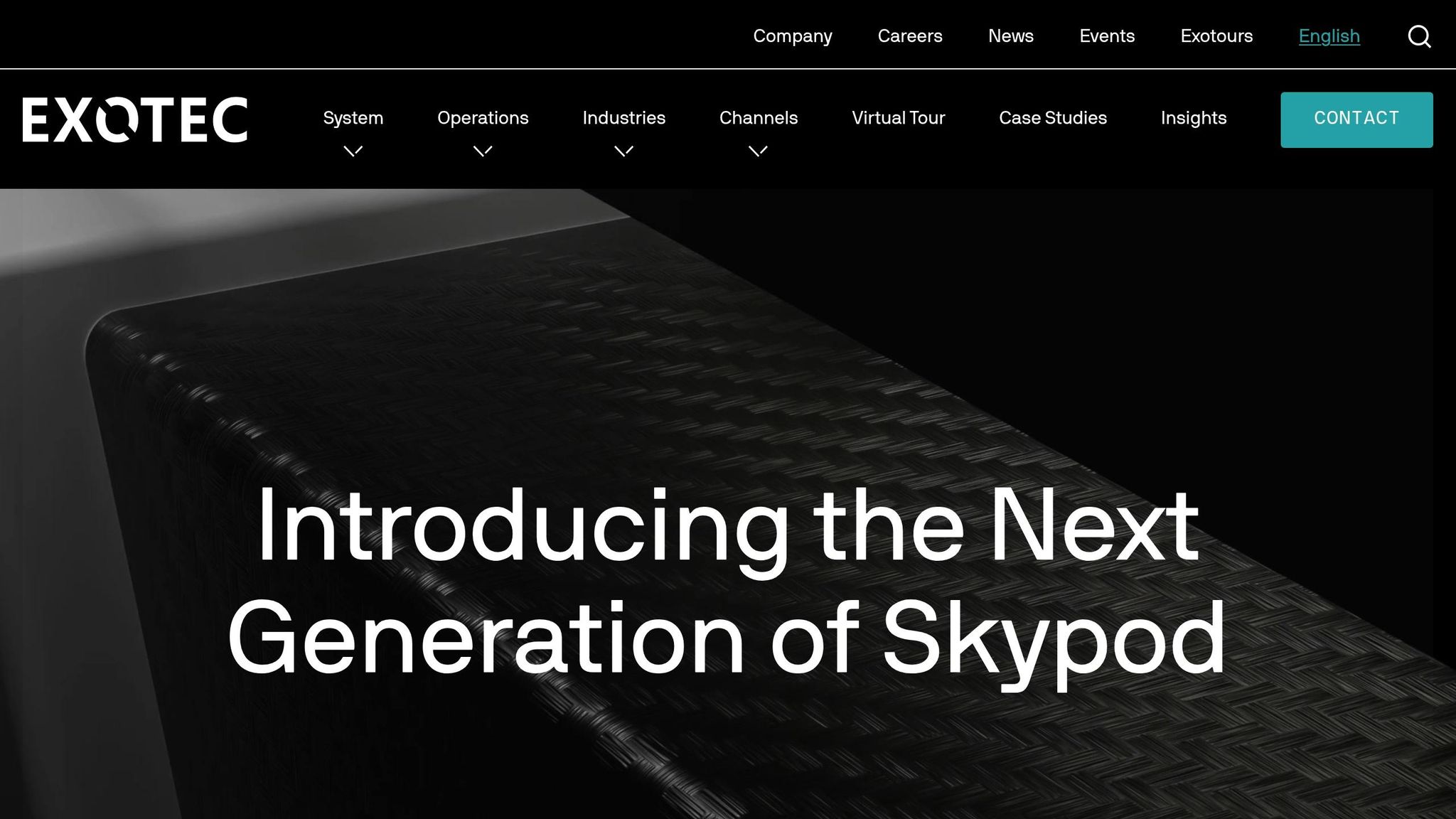

Exotec's Skypod system is another standout example, designed to meet the growing demands of large-scale e-commerce operations. This mobile automated storage and retrieval solution features a modular design, enabling businesses to scale by adding robots, stations, and storage racks as needed.

E.Leclerc Seclin and Supplyweb have both deployed this system to enhance their fulfillment capabilities. E.Leclerc Seclin's setup - comprising 30 robots, 1,680 bins, and 12 delivery stations - has increased capacity to 1,200 daily orders while cutting wait times by 70% and boosting order volume by 50%. Supplyweb's installation, featuring 24 robots within a 927 m² space, allows just two employees to manage over 530 lines per hour, with access to 192,000 storage locations. Similarly, PC Componentes tripled productivity, processing up to 960 lines per hour with only three employees, showcasing the system's scalability.

"We chose Exotec for its storage density and its operational flexibility. Robotic advancements have enabled us to set up a larger buffer area for prepared orders within the system." - Maxence Maurice, CEO of E. Leclerc Seclin

"The picking stations are very ergonomic and easy to use. Any newcomer with an hour's training can start preparing orders." - Ludovic Felix, Picking Manager, Supplyweb

The case studies highlight how AI-driven systems are delivering measurable advancements across various operational areas, from efficiency to cost savings and scalability.

AI-powered order picking systems are setting new benchmarks for speed and precision, achieving up to 1,400 picks per hour with an impressive 99% accuracy. In one controlled warehouse study, the use of explainable AI cut average order picking time by 23% by optimizing storage location assignments. These enhancements not only improve operational performance but also reduce labor demands, reshaping how workforces operate.

Integrating AI into operations has proven to significantly reduce labor costs while increasing efficiency. Take Amazon, for example: after introducing robotics in its fulfillment centers in 2012, the company achieved a 75% reduction in picking and packing times, addressing labor shortages while boosting overall productivity. Lior Tal, CEO of Cyngn, emphasized the collaborative potential of AI, stating:

"At Cyngn, we believe the true promise of this technology lies in collaboration, reshaping workforce dynamics in measurable ways".

In another instance, Barrett Distribution leveraged Gather AI's solutions to save over $250,000 and achieve a return on investment in under a year. These cost reductions not only enhance profitability but also enable businesses to scale more effectively.

Beyond labor efficiency, AI is revolutionizing scalability by offering real-time inventory data. For example, Walmart integrated machine learning into its supply chain management in 2024, analyzing sales data alongside external factors to minimize stockouts and streamline inventory. Similarly, Amazon employs advanced robotics and computer vision to monitor stock levels and predict demand shifts in real time.

The market for inventory management software reflects this growing reliance on AI, with projections showing growth from $2.19 billion in 2024 to $7.52 billion by 2034, driven by a compound annual growth rate of 13.1%. Ocado also demonstrates the power of predictive analytics in its fulfillment centers, dynamically adjusting inventory levels to match demand fluctuations while reducing waste and operational costs.

These advancements showcase how AI is reshaping supply chain operations, offering businesses the tools to adapt, scale, and thrive in a competitive landscape.

AI-powered order picking systems are reshaping warehouse operations, but implementing these technologies isn't without hurdles. At the same time, emerging trends are paving the way for exciting advancements in warehouse automation, offering businesses opportunities to stay ahead of the competition.

A staggering 85% of AI projects fail to meet their intended goals. This high failure rate highlights the complex challenges businesses face when adopting AI technologies.

One major issue is the difficulty of integrating AI with legacy warehouse systems. These older systems often can't communicate effectively with modern AI solutions, leading to expensive compatibility problems. However, there are success stories. For instance, Sienzi Logistics in Turkey tackled this challenge by integrating an AI-based system from Kairos Logic AB into their existing ERP system. They used an application programming interface (API) to enable their warehouse management system to share customer order data with the AI platform, which then generated optimized picking routes.

Another barrier is the fear of job displacement, which can create resistance to AI adoption. Clear communication and thorough employee training can help address these concerns.

Data quality is another critical factor. AI systems rely on clean, standardized data to function properly, but many warehouses deal with inconsistent or outdated information spread across multiple platforms. Businesses must prioritize data cleaning and standardization to ensure their AI systems work as intended.

Cost is also a significant obstacle. The high initial investment required for AI can discourage many companies. Adopting a phased approach - starting with small-scale pilot tests in controlled environments - can help spread costs over time, reduce risks, and demonstrate the technology's value before full-scale implementation.

There are also examples of overcoming integration challenges. Fiege, in collaboration with Nomagic, introduced the justInduct Robot, which required no integration on the Warehouse Control System side. Their justPick robots were also adapted to work seamlessly with existing spring floor trolleys. Jens Veltel, Director of Warehouse Automation at Fiege, shared his experience:

"Nomagic delivered tailored solutions for AutoStore picking and Pocket Sorter induct, working closely with our team to solve our specific challenge".

Despite these challenges, the future of AI in warehousing is bright, with emerging trends pointing toward transformative changes.

Several trends are set to redefine order picking operations in the coming years.

Adaptive robotics is one of the most significant advancements on the horizon. Unlike traditional robots limited to single tasks, AI-powered systems can handle multiple functions and adjust to changing workflows. Matt Charles, Executive Director of Global Accounts, explains:

"AI is driving a huge shift towards flexible automation in warehouses. Instead of robots being programmed for one specific task, AI allows them to handle a wider variety of parts and adapt to changing workflows, leading to more efficient and productive facilities".

This adaptability, combined with advancements like swarm robotics, will make it possible to tackle increasingly complex tasks while optimizing workflows.

Collaborative robots (cobots) are another growing trend. These robots work alongside human employees, enhancing productivity without replacing the workforce entirely. Studies show that cobots can boost efficiency by 30%, making them an attractive option for companies aiming to improve operations while prioritizing worker well-being.

AI-powered optimization is also evolving rapidly. Predictive analytics, powered by AI, enables warehouses to anticipate demand spikes, streamline inventory, and eliminate bottlenecks. Karolina Pulido, CEO, highlights the benefits:

"Dynamic forecasting powered by AI and real-time data is giving top companies an edge. With instant insights, they can align stock levels and resources precisely with demand - keeping inventory lean and responsive".

Robotics as a Service (RaaS) is lowering the barriers to automation by offering subscription-based access to advanced robotics. This model makes it easier for smaller businesses to adopt cutting-edge solutions without large upfront investments, making AI adoption more accessible across the industry.

The numbers back up these trends. UPS predicts a 50% increase in AI adoption for route optimization among logistics providers in 2024. Additionally, nearly 50% of logistics companies plan to implement AI for autonomous warehouse operations by the end of 2024. Only 16% of organizations expect to avoid AI entirely over the next five years, signaling widespread acceptance of these technologies.

Finally, 5G connectivity is set to supercharge AI adoption by enabling real-time communication and operation of AI systems. This will significantly enhance speed and efficiency in warehouse environments. Combined with sustainable practices like energy-efficient robotics and solar-powered systems, these advancements point to a future of highly efficient and environmentally conscious warehouses.

For businesses aiming to thrive in this evolving landscape, the key is to develop flexible automation strategies that embrace human-robot collaboration while keeping sustainability and scalability front and center.

AI-powered order picking systems are transforming how businesses operate, delivering measurable improvements in efficiency and cost savings. According to McKinsey, companies adopting AI solutions have seen a 15% reduction in costs, a 35% decrease in inventory levels, and a 65% boost in service levels. Similarly, Honeywell's AI-driven robotic system has achieved a 40% increase in throughput - a testament to the power of these technologies.

The adoption of AI is no longer a niche trend. A significant 65% of organizations now report regular use of AI in their operations, while only 16% remain hesitant about integrating AI within the next five years. This widespread shift marks a pivotal moment in warehouse management, where AI is becoming a cornerstone of operational strategy.

To maximize the potential of AI, businesses need clear and measurable goals. AI systems excel at collecting and analyzing real-time data, automating repetitive processes, and optimizing workflows. For example, a Griddynamics case study demonstrated how explainable AI solved a storage location assignment issue, cutting average order picking time by 23%. This type of integration not only streamlines operations but also enhances employee productivity by allowing workers to focus on more strategic, high-value tasks.

The benefits of AI extend far beyond immediate savings. These systems provide the flexibility to adapt to fluctuating order volumes and new product launches, ensuring faster fulfillment, greater accuracy, and consistent service levels. This scalability gives businesses the tools to stay competitive in a rapidly changing market.

AI in order picking has already proven its value, delivering tangible results today. Companies that embrace pilot projects and develop well-defined implementation plans position themselves to lead in operational efficiency and customer satisfaction. By leveraging AI technologies like computer vision and custom machine learning models, businesses can overcome challenges and build scalable, future-ready operations.

For expert guidance on integrating AI into your warehouse systems, consider partnering with Artech Digital. Their tailored solutions, including advanced AI technologies, can help you achieve measurable success and streamline your operations.

AI-powered order picking systems are transforming how warehouses handle demand surges and seasonal peaks. By leveraging predictive analytics and real-time data, these systems can analyze historical sales patterns, customer behavior, and external factors to anticipate demand shifts. This allows warehouses to fine-tune inventory levels and streamline picking routes, helping to avoid stockouts and boost efficiency during busy periods, such as the holiday season.

Another game-changing feature is the use of digital twins - virtual models that replicate warehouse operations. These digital replicas let warehouses test and adjust workflows or inventory layouts in real time, making it easier to adapt without overhauling physical infrastructure. With their ability to learn and evolve continuously, AI systems not only enhance productivity but also cut delays and elevate customer satisfaction when demand is at its highest.

Integrating AI into warehouse systems isn't without its challenges. One of the biggest obstacles is data availability and quality - AI thrives on accurate, well-structured data to produce reliable results. Another issue is compatibility with legacy systems; older infrastructure can make implementation tricky and drive up costs. On top of that, employee resistance can slow things down, especially if workers are unfamiliar with AI tools or worry about job security.

To tackle these challenges, businesses can begin by refining their data management practices, ensuring the data used for AI is clean and easily accessible. Taking a gradual approach - like starting with small pilot projects - can also ease the transition from outdated systems, keeping disruptions to a minimum. And to address employee concerns, investing in training programs and fostering a forward-thinking mindset can help teams adapt to AI, paving the way for smoother integration and long-term progress.

The partnership between robots and human workers in warehouses is transforming how tasks are handled, blending their unique strengths to boost efficiency and cut costs. Robots handle repetitive and physically taxing jobs like lifting, sorting, and moving items. Meanwhile, human workers focus on tasks that require decision-making and problem-solving, such as quality checks and inventory management. This approach not only increases productivity but also minimizes workplace injuries and reduces costs tied to compensation and downtime.

Robotic systems also excel in speeding up and improving the accuracy of order picking and packing. This means fewer mistakes and faster order fulfillment, allowing businesses to save on operational costs while providing quicker, more reliable service to customers. Together, humans and robots create a warehouse setup that’s faster, safer, and more cost-effective.

.png)

.png)